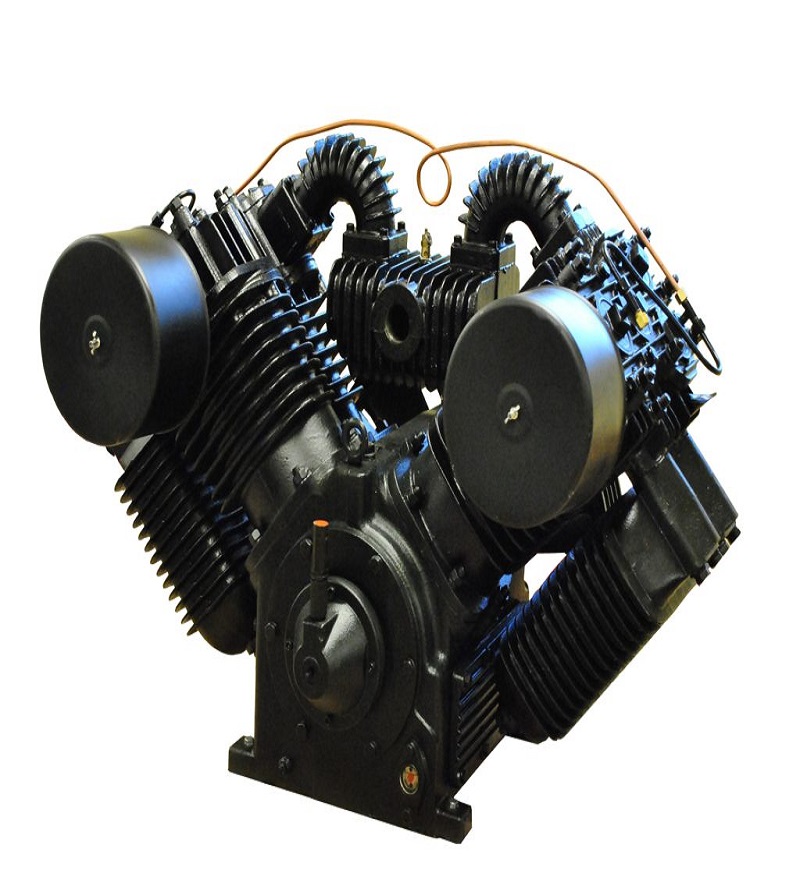

EutAir Leading Reciprocating Air Compressor Provider in India

For enterprises like auto body shops, small garages, and do-it-yourself projects, EutAir designs and manufactures durable, industry-leading single stage and two stage ingersoll rand air compressor and accessories. Renewable parts ensure our reciprocating systems are low-cost and easy to maintain. Because of how well thought out their designs are, you can expect cheap maintenance costs and a quick return on investment thanks to the straightforward accessibility of the pumps' individual parts.